Custom Plastic Injection Molding

Achieve efficient plastic injection molding for your prototypes and production parts, accelerating your journey from design to market. Contact us for a detailed project review and quote.

- High Quality Plastic Parts

- Professional DFM Analysis

- Rapid Turnaround

- Wide Material and Finish Selection

Complete Guide to Injection Molding Services

Our Manufacturing Capabilities

At Moldatech, we offer plastic injection molding, liquid silicone rubber (LSR) molding, in mold labelling(IML), overmolding, insert molding, prototyping and on-demand manufacturing to ISO 9001 quality standards. We support your project development from the initial idea through to full-scale production, focusing on quality and efficient delivery.

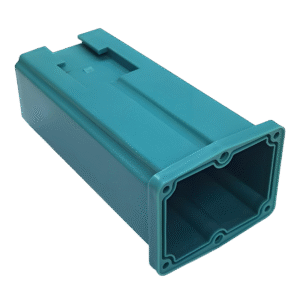

Plastic Injection Molding

Plastic injection molding is a process where thermoplastic resin is heated and injected into a mold cavity, forming precise, durable parts for functional or structural use.

Liquid Silicone Rubber Molding

Liquid silicone rubber molding(LSR) uses a two-part silicone material mixed and heat-cured inside the mold, producing flexible, stable parts suitable for demanding applications.

In Mold Labelling(IML)

In mold labelling(IML) embeds pre-printed labels into plastic parts during molding, creating a permanent bond between label and part surface for durable branding or instructions.

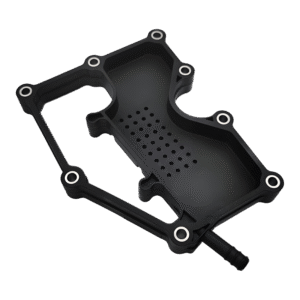

Overmolding

Overmolding layers a soft or secondary material over a molded part, adding grip, insulation, or protection while improving ergonomics and integration.

Insert Molding

Insert molding forms plastic parts around metal or other inserts in the mold, combining materials into one component to improve strength and reduce assembly processes.

Prototyping

Prototyping turns design concepts into physical samples before mass production, enabling testing of fit, function, and manufacturability for faster, risk-reduced development.

How Custom Plastic Injection Molding Works?

- Setting up the mold to the injection molding machine.

- Feeding and melting the thermoplastic.

- Injecting the plastic into the mold.

- Holding and Cooling.

- Ejecting and Finishing processes.

The injection molding process can be repeated hundreds or even thousands of times quickly, helping to offset the tooling costs and reducing the cost per unit to just a few dollars or less. At Moldatech, we offer molds with anywhere from a single cavity to hundreds of cavities, enabling the production of large volumes of parts. The manufacturing cycle time depends on the material, size, and complexity of the part.

Get precise and fast results with our custom injection molding services. Quickly move from prototype to full-scale production. Request your free quote today!

Common Applications

Injection molding is used in many industries. Our expert team provides production solutions to accelerate your product to market.

Medical devices and Dental

Automotive

Aerospace

Electronics

Consumer Products

Energy

Our Plastic Injection Molding Facility

Curious about where your plastic parts take shape? Our dedicated facility is set up for precision plastic injection molding. We use well-maintained equipment and organized processes to produce your components efficiently. This focus ensures you receive reliable parts, supporting your project timelines and quality needs.

Injection Molding Materials

Wondering which plastic best suits your molded parts? We handle a range of thermoplastic materials for various applications. Our team can help you consider factors like strength, flexibility, and cost-effectiveness. This ensures your components meet performance needs and project goals.

| Material | Characteristics | Price | Technical Information | Common Application |

|---|---|---|---|---|

| Acrylonitrile Butadiene Styrene (ABS) |

+ Durable, with good impact and heat resistance + Good dimensions + Can be molded into complex objects - Prone to warping - Cracking under certain conditions (exposure to UV light and heat) | $$ |

Shrinkage: 0.4% to 0.8% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Automotive parts, toys, electronic housings, luggage and kitchen appliances |

| Polypropylene (PP) |

+ High strength-to-weight ratio + Good chemical resistance + Low cost + Easy to process and can be molded into a variety of shapes and sizes - Not as strong as other materials such as ABS - Not suitable for high-stress applications - Prone to warping and shrinking | $ |

Shrinkage: 1.0% to 2.5% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Packaging, containers, automotive parts, medical devices |

| Polyamide 6 (PA6) |

+ High tensile strength + Good toughness and abrasion resistance + Absorption + Good chemical resistance + Good dimensional stability and can be easily molded into complex shapes - Prone to warping and shrinkage during the injection molding process | $$$ |

Shrinkage: 1.5% to 3.0% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Gears, bearings, electrical components, automotive parts |

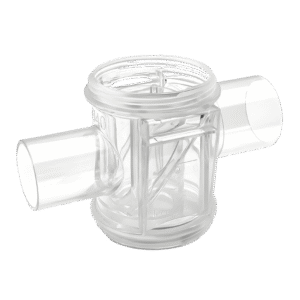

| Polymethyl Methacrylate (PMMA) |

+ High transparency + Good impact strength + Weather resistance + Easily molded into complex shapes + Good dimensional stability - Prone to scratching and cracking under certain conditions, such as exposure to harsh chemicals or high temperatures - More expensive than other materials such as ABS or PP | $$$ |

Shrinkage: 0.2% to 1.5% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Lighting fixtures, automotive lenses, medical devices |

| Polycarbonate (PC) |

+ High impact resistance, transparency, and heat resistance + Easily molded into a variety of shapes and sizes - More expensive than other materials such as ABS or PP - Prone to warping and shrinking during the injection molding process | $$$$ |

Shrinkage: 0.5% to 0.8% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Electronic components, automotive parts, medical devices, safety helmets |

| Polyoxymethylene (POM) |

+ High strength, stiffness and dimensional stability + Good chemical resistance + Can be easily molded into complex shapes with tight tolerances - Prone to warping and cracking under certain conditions, such as exposure to UV light or high temperatures - More expensive than other materials such as ABS or PP | $$$ |

Shrinkage: 1.5% to 2.5% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Gear wheels, bearings, electrical components |

| Polyether Ether Ketone (PEEK) |

+ Excellent mechanical properties, including high strength, stiffness, and creep resistance + Good chemical resistance and can withstand high temperatures and harsh environments - More expensive than other materials such as ABS or PP - Prone to warping and shrinking during the injection molding process | $$$$$ |

Shrinkage: 1.0% to 3.0% Tolerances: +/- 0.002 inches (0.0508 mm) to +/- 0.005 inches (0.127 mm) | Aerospace components, medical devices, electrical connector |

| Polyethylene (PE) |

+ Low cost, toughness, and chemical resistance + Easily molded into a variety of shapes and sizes - Not as strong as other materials such as ABS or PC - Prone to warping and shrinking | $ |

Shrinkage: 1.5% to 3.5% Tolerances: +/- 0.010 inches (0.254 mm) to +/- 0.020 inches (0.508 mm) | Packaging, containers, toys |

| Polyethylene Terephthalate (PET) |

+ High strength, toughness, and transparency - Prone to warping and shrinking | $ |

Shrinkage: 0.2% to 1.0% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Bottles, jars, containers |

| Polyvinyl Chloride (PVC) |

+ Good chemical resistance, low cost, and versatility + Easily molded into a variety of shapes and sizes - Not as strong as other materials such as ABS or PC - Can release harmful fumes when overheated or burned, so proper ventilation and safety precautions are necessary when working with this material | $ |

Shrinkage: 0.2% to 1.0% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Pipes, electrical cable insulation, inflatable products |

| Polylactic Acid (PLA) |

+ Biodegradable and derived from renewable resources (like corn starch) + Easy to mold with low processing temperatures + Good surface finish and dimensional accuracy - Brittle compared to other plastics - Low heat resistance | $$ |

Shrinkage: 0.2% to 0.8% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Prototypes, disposable packaging, biodegradable products |

| Polytetrafluoroethylene (PTFE) |

+ Excellent chemical resistance, low coefficient of friction, and high temperature resistance - More expensive than other materials such as ABS or PP - Prone to warping and shrinking during the injection molding process | $$$$$ |

Shrinkage: 1.0% to 2.0% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Seals, gaskets, bearings, chemical processing equipment |

| Thermoplastic Polyurethane (TPU) |

+ High elasticity, toughness, and resistance to abrasion and chemicals + Easily molded into a variety of shapes and sizes - More expensive than other materials like ABS or PP | $$$ |

Shrinkage: 0.5% to 1.5% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Footwear, sporting goods, medical devices, cable insulation, protective cases |

| High-Density Polyethylene (HDPE) |

+ High strength, chemical resistance, and low cost + Easily molded into a variety of shapes and sizes - Not as strong as other materials | $ |

Shrinkage: 1.5% to 3.5% Tolerances: +/- 0.010 inches (0.254 mm) to +/- 0.020 inches (0.508 mm) | Piping, containers, toys |

| Low-Density Polyethylene (LDPE) |

+ High flexibility, toughness, and chemical resistance + Easily molded into a variety of shapes and sizes - Not as strong as other materials | $ |

Shrinkage: 1.5% to 3.5% Tolerances: +/- 0.010 inches (0.254 mm) to +/- 0.020 inches (0.508 mm) | Film packaging, containers, toys |

| Polyphenylsulfone (PPSU) |

+ Excellent impact resistance and toughness + Outstanding hydrolysis resistance, suitable for repeated steam sterilization + Good chemical resistance - Higher cost than standard thermoplastics - Prone to slight discoloration over time | $$$$ |

Shrinkage: 0.2% to 0.7% Tolerances: +/- 0.002 inches (0.0508 mm) to +/- 0.005 inches (0.127 mm) | Medical devices, sterilizable components, aerospace parts |

| Polyetherimide (PEI) |

+ High strength and stiffness + Excellent heat resistance + Good flame retardancy without additives - Higher cost compared to common engineering plastics - Can be brittle in thin-wall applications | $$$$ |

Shrinkage: 0.5% to 0.7% Tolerances: +/- 0.002 inches (0.0508 mm) to +/- 0.005 inches (0.127 mm) | Electrical components, automotive under-hood parts, aerospace |

| Polyamide 46 (PA46) |

+ Superior mechanical strength at high temperatures + Excellent wear and abrasion resistance + Good chemical resistance - More expensive than standard nylons - Prone to moisture absorption | $$$ |

Shrinkage: 0.5% to 1.2% Tolerances: +/- 0.005 inches (0.127 mm) to +/- 0.010 inches (0.254 mm) | Gears, bearings, engine parts, connectors |

| Liquid Crystal Polymer (LCP) |

+ Exceptional dimensional stability + High strength and stiffness at thin wall sections + Excellent chemical resistance + Naturally flame retardant - Higher cost - Brittle under certain conditions | $$$$ |

Shrinkage: 0.1% to 0.3% Tolerances: +/- 0.002 inches (0.0508 mm) to +/- 0.005 inches (0.127 mm) | Electronic connectors, micro gears, automotive sensors |

| Polyphthalamide (PPA) |

+ Excellent mechanical properties at high temperatures + Superior chemical resistance + Good dimensional stability for complex parts - Higher processing temperature required - More expensive than standard nylons | $$$$ |

Shrinkage: 0.2% to 0.6% Tolerances: +/- 0.002 inches (0.0508 mm) to +/- 0.005 inches (0.127 mm) | Automotive under-hood parts, pump housings, industrial equipment |

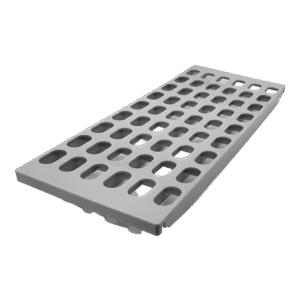

Available Surface Finishes for Injection Molding

With years of experience in custom molding, we provide injection molding services tailored to your product requirements. A wide range of surface finish options is available to help ensure your parts meet both functional and aesthetic needs. If you have specific surface finish requirements beyond the standard options, feel free to contact us for further support.

- As Molded

- Polishing

- Pad Printing

- Matte

- Etching

- Custom Finishing

- SPI Finishes

- Silk Screening

- Glossy

- Painting

- Laser Engraving

Injection Molding FAQs

Injection molding is ideal for producing large quantities of plastic parts with consistent quality and precision. It supports complex geometries, tight tolerances, and a wide range of materials. Once the mold is made, the per-unit cost is low, making it suitable for mass production.

Injection molding is widely used in industries like automotive, consumer electronics, medical devices, and industrial equipment. Typical applications include housings, gears, brackets, enclosures, and components that require durability, accuracy, or functional complexity.

The total cost depends on several factors, including the complexity of the part, the number of cavities in the mold, material selection, and production volume. While the initial mold investment is higher, the per-unit cost decreases significantly with larger production runs.

Yes. We support both low-volume prototyping and high-volume production molding. Whether you need a small batch for testing or large-scale manufacturing, we can provide the right solution to fit your production needs.

Standard tolerances for injection-molded parts typically range from ±0.005 inches (0.127 mm) to ±0.010 inches (0.254 mm), depending on the material and part design. We can advise on achievable tolerances after reviewing your specific project.

Prototype molds are typically made from softer materials like aluminum and are used for short runs or product validation. Production molds are made from hardened steel for long-term use, supporting thousands or millions of parts with greater durability and consistency.

No. Aluminum molds generally have a shorter overall lifespan compared to steel molds. While aluminum is suitable for prototypes and low to medium production volumes, steel molds are preferred for large-scale production runs due to their excellent durability and long-term stability.

Aluminum molds can be used for moderate production volumes, especially for simpler parts or projects where fast turnaround is required. For high-volume, long-term production, steel molds are recommended due to their superior wear resistance.

The maximum part size depends on the specific injection molding equipment used. We can support both small precision parts and larger components. Please contact us with your design, and we will confirm feasibility based on your specifications.

We offer a wide selection of thermoplastic and engineering-grade materials, including ABS, PC, PP, POM, PA, PEEK, TPU, and many others. Material choice depends on your part’s functional, mechanical, and environmental requirements.

Lead time for mold production typically ranges from 3 to 6 weeks, depending on the complexity of the part, number of cavities, and specific project requirements. We offer expedited options for urgent projects.

Plastic injection molding uses thermoplastic materials, which harden when cooled. LSR molding uses liquid silicone rubber, which is heat-cured inside the mold. LSR is often used for flexible, medical-grade, or high-temperature applications, while plastic is preferred for rigid components.